Case Study

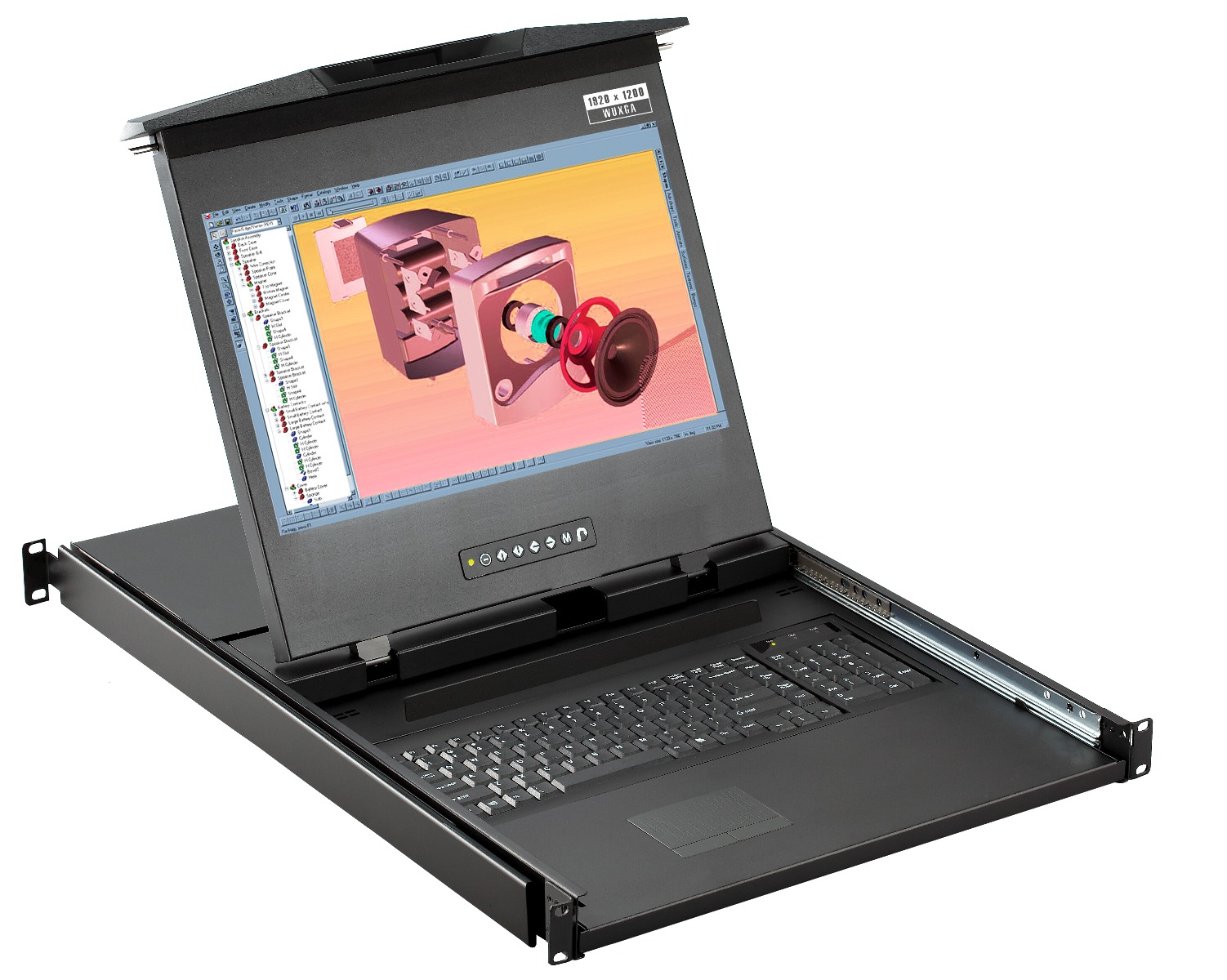

1U Rackmount Monitor or 1U Computer Work Station?

Client Requirements – Build a 1U thin client workstation integrated into a 1U Rackmount Monitor Drawer, including LCD, Keyboard, and mouse. The 1U Chassis will mount in a 30” deep 6U rugged aluminum case.

The initial request -

Thin Client specifications

o Removable hard-disk drive (2.5” SSD Mobile Rack Device Bay)

o CPU

o Memory capacity

o At least 1 GbE port

Monitor specifications

• Power consumption (nominal & maximum)

• Environmental Storage & Operational temperature range

• Weight

• Dimensions

• Mean Time Between Failure

• Time to deliver from receipt of PO

• Warranty Additional specifications for the project Removable Hard Drive:

• The removable hard drive is a requirement.

The removable drive is mandatory as there is a requirement to replace drives without the need to bench test a system

Thin Client:

• A Hewlett Packard client is sufficient.

• Note that the video capability need not be reflected in the KVM solution Below are specific environmental conditions

Specific Environmental Storage Requirements:

• Temp.: -20°C – 50°C

• Humidity: Relative Humidity 1% to 100% (tending toward saturation), with condensation

• Altitude: -61 meters to 3,048 meters Specific Environmental Operating Requirements:

• Temp.: 5°C – 30°C • Humidity: Relative Humidity maintained within 20% to 80% with no condensation

• Altitude: -61 meters to 2,438 meters

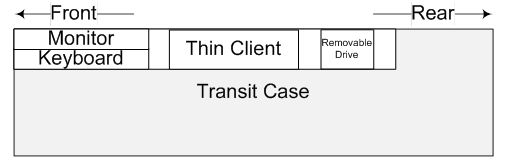

Original rough sketch -

The proposed solution – Removable SSD (solid state flash drive, non spinning)

CPU: Intel Bay Trail Series Processor Quad–Core Up to 1,83 GHz

OS: ThinX OS Flash: 16 GB

Ram: 2GB Network: RJ-45 VDI

Connection: RDP 8 / Citrix XenDesktop / VDI-In-a-Box / HDX, VMware Horizon View w/ PCoIP, 2X, v

Workspace Management: Xcalibur Global

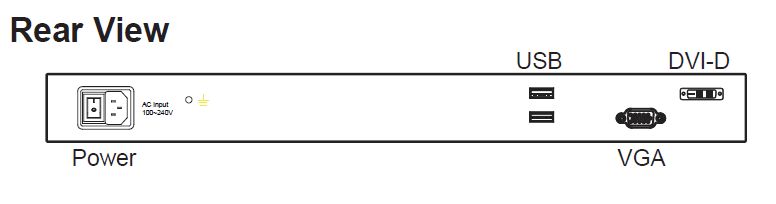

Input/Output: 6 X USB 2.0 ports Display Supported: DVI-1 port

Resolution: 1920X1200 True color (32bit) Audio

Support: Stereo Audio Output Power: DO 6V/2A 100-240V AO, 50/60 Hz

Consumption: Running 3W, Max 6W, Standby <1W Dimensions: 6” X 4.25” X 1.25” Weight: 365gm or 0.8lbs

MTBF: Warranty: Three Years

Response – the removable drive is mandatory as there is a requirement to replace drives without the need to bench test a system. The customer only had 1U of space for a mobile application with a requirement to include a 1U Rackmount Console and keyboard along with a SBC (single board computer) integrated to keep all hardware contained in a tight compact configuration.

Standard Rear I/O ports for 1U Rackmount Monitor -

Customer request for a 1U 19” Rackmount Monitor with integrated keyboard. The customer request included integrating a small single board computer with SSD.  The solution – custom build the rear back chassis with custom I/O ports to accept the SBC Computer solution. The 1U rackmount computer/monitor/keyboard included a 2.5” Solid State Disc (SSD) Mobile Rack Device Bay with a 2.5GB SSD Drive, with installed Linux CentOS. The internal power supply was also upgraded to support all electronic hardware. By combining all of the above into a compact 1U computer, the customer was able to fit this solution into their rugged compact transit case for the mobile integrated application. For this or other CUSTOM solutions, contact us at 800-542-2489, sales@rackmountsales.com

The solution – custom build the rear back chassis with custom I/O ports to accept the SBC Computer solution. The 1U rackmount computer/monitor/keyboard included a 2.5” Solid State Disc (SSD) Mobile Rack Device Bay with a 2.5GB SSD Drive, with installed Linux CentOS. The internal power supply was also upgraded to support all electronic hardware. By combining all of the above into a compact 1U computer, the customer was able to fit this solution into their rugged compact transit case for the mobile integrated application. For this or other CUSTOM solutions, contact us at 800-542-2489, sales@rackmountsales.com

_________________________________________________________________________________________

Case Study

Application – the customer has communication racks with a requirement to mount a 1U rackmount monitor that is only accessed on a limited basis. The server rack is primarily housing a large amount of cables connected to switches which hang vertically in the rack. The large volume of cables, along with the switch technology take up a significant amount of space in the racks as the cables are running vertically in the rack. Mounting a traditional 1U rackmount monitor in the middle of the rack that is not accessed very often is not an ideal set up for the application.

The customer request is to store a 1U console drawer in the rack without blocking the vertical space in the rack that is mostly populated with the dense amount of cables. When the monitor is needed, it needs to be easily accessible. The suggested solution is the build a vertical hinge on the LH side of the 1U LCD drawer so when it is not in use, it can be stored in the rack vertically, out of the way of the cables. The design incorporated a solution that takes 10 seconds to deploy by securely storing the 1U LCD in a vertical position and anchoring it in place with a simple bracket that attaches to the left hand front rail of a 19” EIA rack rail.

To mount the monitor properly, a request was made to get the .dwg drawings for the rack manufacturer so the custom brackets could be designed to specifically mount in the customers’ existing rack. Once the monitor is mounted, it can easily be pivoted into a horizontal position for normal access as a traditional, pull out, rackmount console drawer.

Steps to accessing the 1U Monitor – Pivot the monitor into a horizontal position, pull the 1U drawer out, flip up the monitor, and begin typing as if it were a traditionally mounted 1U rackmount monitor. When done accessing the monitor, the same motion is used to store it back in the home vertical position – close the LCD Panel, push the 1U LCD Drawer back into the home stored position in the rack, and then pivot the drawer from right to left to store it back to its vertical position. The cable management arm stays with the drawer so the LCD VGA & USB cables and power supply are out of the way when stored.

https://youtube.com/shorts/G2PHVEZJrQA?feature=share

This is a sample of the custom solutions Crystal Image Technologies can provide. Once we know the application and specific project needs, we have the flexibility to design to a specific requirement. In this case, the customer monitor solution was based off a minimum order requirement of 4 units with a forecast of 10 to 20 units in the future. There was a NRE (non-recurring engineering fee) to complete the initial engineering work. Once the design was signed off, the manufacturing lead time was four weeks. Installation instructions were provided with the shipment as well as the video showing the end results. Crystal Image Technologies provides custom solutions for small and large applications including sheet metal, and electronics requirements as well as MILSTD-801F/G compliant solutions.